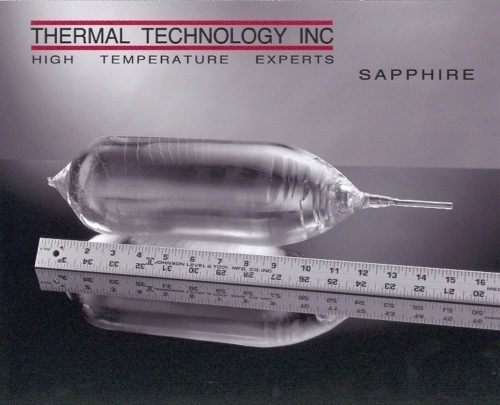

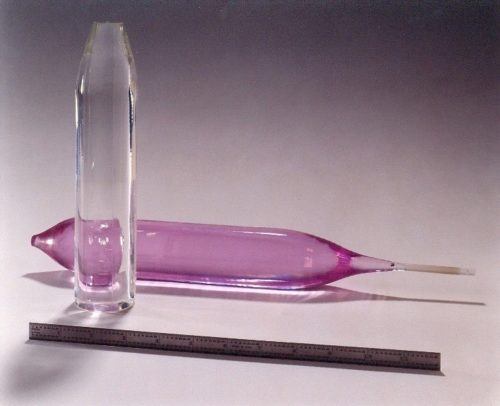

Thermal Technology’s crystal growth furnace systems provide the two most important parameters necessary for critical growth: stability and control. Both are necessary to achieve consistency, repeatability, and uniformity – the keys to successful crystal growth in the laboratory and in production.

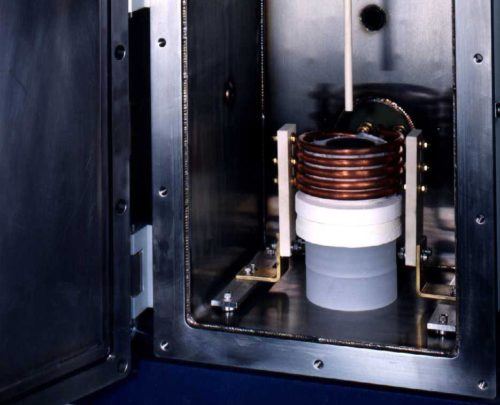

Crystal growth demands smooth, highly constant, vibration-free motions with large and dynamic ranges. They must be programmable first and second derivatives and multi-axis configurations. Stability provides the crystal grower with a known and constant environment for demanding crystal growth, as well as uniform, tightly defined temperatures and thermal gradients for consistent melts and zone refining. We provide stability with well-controlled gaseous or vacuum environments.

Thermal Technology’s computer system interface holds temperatures precisely where they are set. And it is able to adjust to constant changes quickly and smoothly with minimal overshoot. The motion system provides pull rates that are highly consistent in both time and space. Our crystal growth furnaces maintain positional through the complete draw cycle. This assures consistent and repeatable results from the crystal growth system.

Whether it is Czochralski, EFG or Kyropoulos growth methods, Thermal Technology provides you with a complete, integrated and constant marriage of the finest, most advanced methods in crystal defined temperatures.

Crystal Growth Furnace Features

With a broad range of equipment and process knowledge, Thermal Technology offers systems for all popular crystal growing methods, including:

- Czochralski

- EFG

- Kyropoulos

From the laboratory to the production floor, Thermal Technology provides:

- Precision Crystal Growing Equipment

- ADC (Automatic Diameter Control)

- Leading Edge Crucible Technologies

- Hot Zone Design Expertise

Crystal Growers

Download Product Brochure

View Brochure

View Brochure